Pass Box is an essential equipment in modern cleanrooms, as the demand for clean environments continues to rise. This is why Pass Box increasingly demonstrates its value

With the increasing demand for clean environments in various industries, Pass Box has become an essential device in modern cleanrooms. In this article, we will explore what Pass Box is and its different types.

What is Pass Box?

A pass box is a pivotal facility strategically placed within cleanroom partition walls. Functioning as a buffer zone, its primary role is to facilitate the seamless transfer of goods between the interior and exterior of a cleanroom.

By preventing disruptions to airflow and air pressure caused by door openings, it plays a critical role in maintaining the pristine conditions of the cleanroom environment. Additionally, it significantly reduces the time operators spend moving in and out, effectively mitigating the risk of dust contamination from external regions. Equipped with a UV lamp for bacteria control, pass boxes feature interlocked doors to prevent direct contact between connected areas.

Benefits of Passbox

- Minimize airflow and air pressure disruption: Pass boxes prevent significant disturbances caused by frequent door openings in cleanrooms, maintaining optimal air quality.

- Reduce personnel movement: They decrease the frequency of personnel entering and exiting the cleanroom, minimizing dust introduction.

- Enhance hygiene: Equipped with UV lamps for bacterial control, pass boxes contribute to a clean and sterile environment.

- Prevent cross-contamination: Interlocked doors ensure only one door remains open at a time, preventing direct contact between connected zones.

Types of Pass Boxes for Clean Rooms

Purpose-based Classification:

- Static Pass Box: Designed for standard transfer purposes.

- Dynamic Pass Box: Incorporates advanced self-cleaning mechanisms.

Door Interlock Modes

- Mechanical Interlocking Pass Box: Utilizes mechanical interlock systems.

- Electronic Interlocking Pass Box: Integrates electronic interlock mechanisms.

Shell Materials:

- Powder-coated steel plate

- Thin steel plate

- Stainless steel pass box

Custom Designs:

Specialized pass box designs tailored to unique customer requirements.

Two Types: Static Pass Box And Dynamic Pass Box

Cleanroom pass boxes are primarily categorized based on their functionalities:

1. Static Pass Box:

- Suitable for transferring materials between cleanrooms with identical cleanliness levels.

- Features UV light and an interlock system, which can be mechanical or electronic.

See more: What is Static Pass Box in Cleanroom

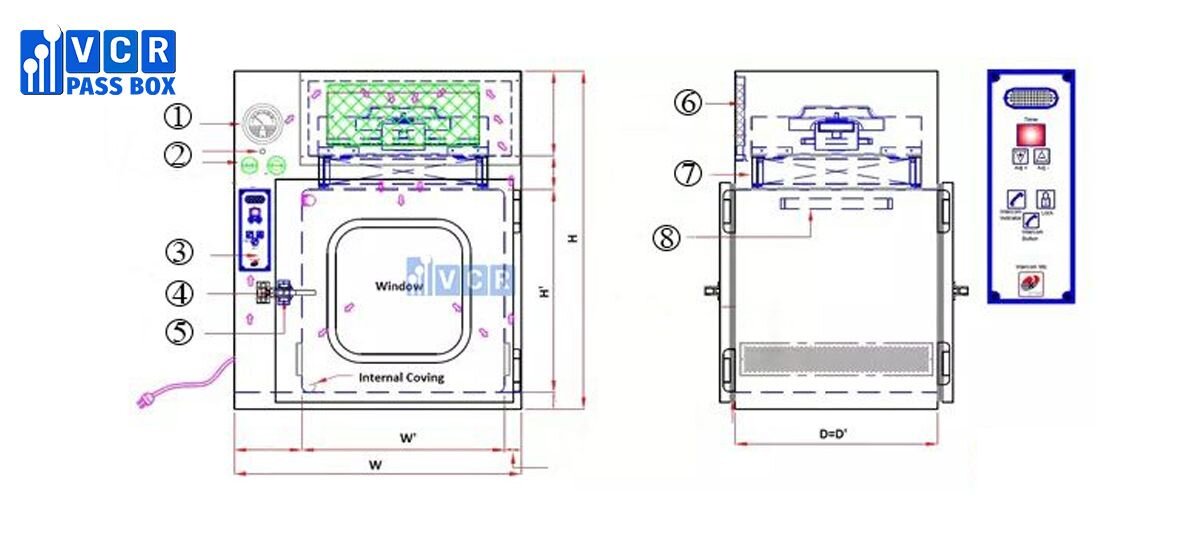

2. Dynamic (Self-Cleaning) Pass Box:

- Ideal for transferring materials between areas with differing cleanliness levels or between a cleanroom and a non-cleanroom environment.

- Includes additional features like HEPA filters (typically H13 or H14, capturing 99.995% of particles at 0.3 microns), a differential pressure gauge, and a motor blower for dust removal.

Structure of Passbox Cleanroom

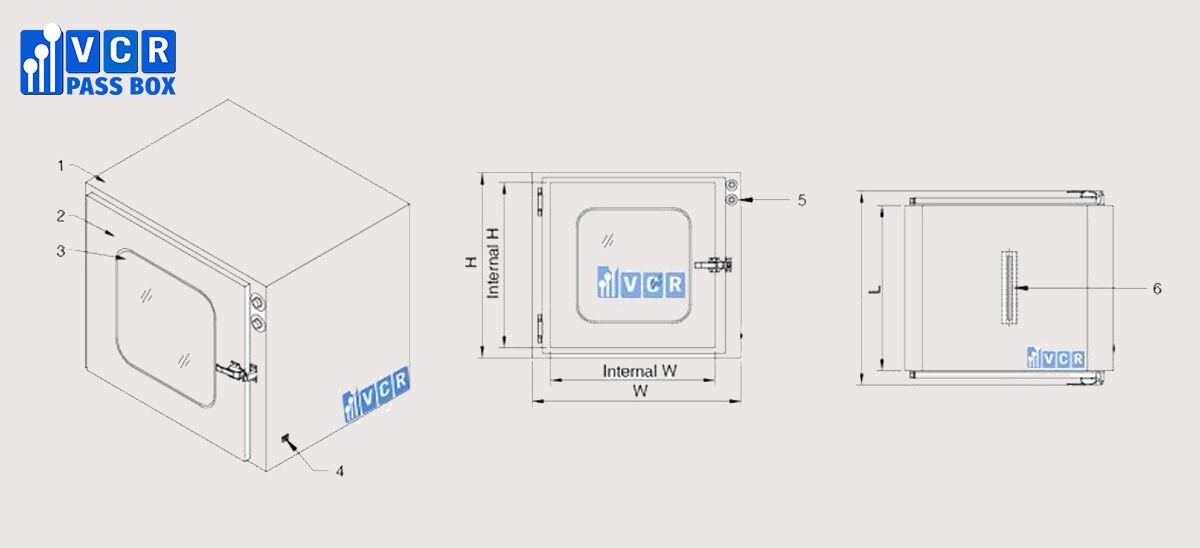

A pass box typically comprises four main components:

1. Casing: Outer shell, often constructed from stainless steel, powder-coated steel, or other suitable materials.

2. Body: Inner chamber, primarily made of 304 stainless steel for enhanced durability and ease of cleaning.

3. Doors: Two interlocked doors with tempered glass windows and sealed edges to prevent airborne particle contamination. Each door features a handle specific to the interlock system type.

4. Lock (Interlock System): Crucial component ensuring only one door opens at a time, preventing cross-contamination. Available in mechanical or electronic versions.

See more: Design of Pass Box Cleanroom

Pass Box Cleanroom Working Principles

Static Pass Box

- Mechanical Interlock: When one door opens, a mechanical linkage physically prevents the other door from opening.

- Electronic Interlock: Utilizes integrated circuits, electromagnetic locks, control panels, and indicator lights. When one door opens and the indicator light is active, the other door remains locked until the first door closes, and its indicator light illuminates.

- UV disinfection cycle: Once materials are placed inside and the door is closed, UV light activates for a set duration (typically 15 minutes) to eliminate bacteria on the transferred objects.

Dynamic Pass Box

- Self-cleaning mechanism: A centrifugal fan draws air, which is then filtered through HEPA filters.

- Pressure equalization: After reaching equal pressure, the filtered air is released into the chamber at a controlled velocity, creating a clean working environment.

- Dust removal: The air outlet can be configured with a nozzle to increase air velocity for targeted dust removal from material surfaces.

See more: 9 Considerations For Dynamic Pass Box

Selection and Maintenance

- Interlock system functionality: Regularly verify the interlock system's proper operation. If issues arise, contact the manufacturer or qualified personnel for repairs.

- UV light maintenance: Monitor UV light performance; replace it promptly if malfunctions occur. Its typical lifespan is around 4,000 hours.

- Filter maintenance (Dynamic Pass Box):

- Replace pre-filters (like G4) every 6 months.

- Change HEPA filters every 6-12 months.

- Regularly monitor the differential pressure gauge to assess filter integrity.

- Cleanliness during maintenance: Ensure all maintenance activities are conducted while maintaining cleanroom hygiene standards.

See more: Dynamic pass box maintenance

Applications of Pass Boxes:

Pass Boxes are used in a variety of industries, including:

- Pharmaceutical: Pass Boxes are used to transfer materials between different areas in a pharmaceutical manufacturing facility, such as the compounding area and the filling area.

- Electronics: Pass Boxes are used to transfer components and materials between different areas in an electronics manufacturing facility, such as the assembly area and the testing area.

- Food and beverage: Pass Boxes are used to transfer food and beverage products between different areas in a food processing facility, such as the preparation area and the packaging area.

- Healthcare: Pass Boxes are used to transfer medical supplies and equipment between different areas in a healthcare facility, such as the operating room and the sterile processing department.

See more:

Pass Box in Cosmetic Cleanroom

Choosing the Right Pass Box:

Our expert team at Vietnam Cleanroom Equipment offers guidance in selecting the ideal pass box for your specific needs.

Request a quote for pass box costs to gain clarity on expectations.

Contact us today via hotline: 090 123 7008 / 090 123 9008.

Pass Boxes are an essential device for maintaining cleanliness in a variety of industries. By preventing cross-contamination, Pass Boxes help to ensure the quality of products and the safety of workers. Elevate your cleanroom efficiency with the precision-engineered pass boxes from Vietnam Cleanroom Equipment.