Pass Box is an indispensable solution in food processing factories to ensure the safe and clean delivery of raw materials and finished products. This article will update the latest Pass Box price list, helping businesses easily choose the right equipment for their needs and budget, while understanding the factors that affect the price.

1. Overview of Pass Box in Food Processing Plants

What is a Pass Box?

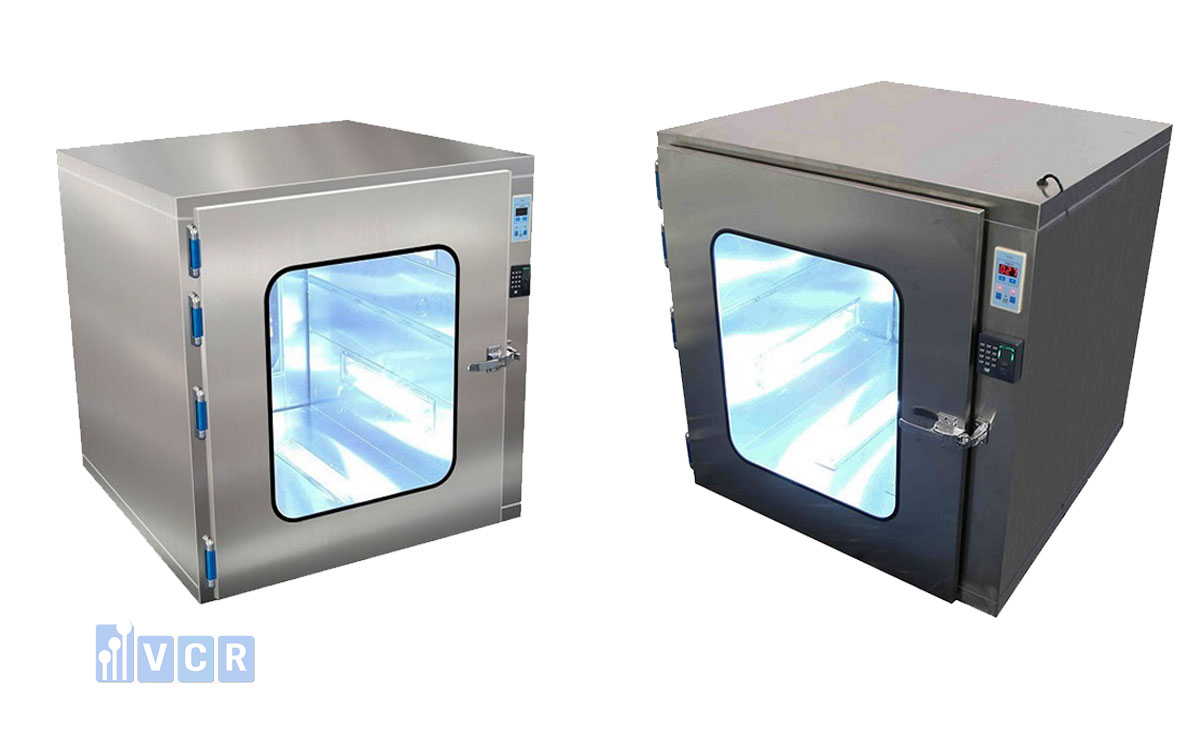

A Pass Box (also known as a Pass-Through Box) is an intermediate device in a cleanroom system that allows the transfer of items between two areas of different cleanliness levels without affecting the pressure, cleanliness, or environmental conditions of each area.

In food processing plants, Pass Boxes are often installed at material-finished goods transfer points or between rooms with different hygiene requirements.

Main purposes:

- Minimize cross-contamination risks from item movement.

- Optimize operational processes by reducing the need to frequently open cleanroom doors.

- Meet the requirements of HACCP, ISO 14644, ISO 22000 standards.

Basic Operating Principle

The Pass Box works on the principle of air isolation between two environments:

- Interlock doors allow only one door to be opened at a time, preventing air from one room from entering the other.

- Some Pass Boxes are equipped with UV lamps to sterilize item surfaces before transfer.

- High-end Pass Boxes have HEPA filters to create a clean airflow inside the transfer chamber.

Transfer process:

- Staff place items into the Pass Box from the sending room → Close the door.

- The system ensures safety locks before allowing the receiving side door to open.

- Staff in the receiving room open the other door and retrieve the items.

Role in Preventing Cross-Contamination & Meeting Standards

In food factories, the Pass Box serves as a critical control point for safe production:

- Prevents cross-contamination between raw material areas and processing/packaging areas.

- Reduces environmental contamination risk from direct door opening.

- Meets HACCP requirements: Assists in managing hazards and critical control points (CCP).

- Complies with ISO 14644: Limits changes in pressure and cleanliness between rooms.

- Aligns with ISO 22000: Supports a comprehensive food safety management system.

2. Types of Pass Box Used in the Food Industry

Manual Pass Box - Features and Applications

Features:

- Fully manual operation, doors opened/closed by hand.

- Mechanical interlock ensures only one door is open at any given time.

- No electronic components or motors, making the unit durable and easy to maintain.

- Common materials: 304 stainless steel or 316 stainless steel (corrosion-resistant, easy to clean).

Applications:

- Suitable for areas with low transfer frequency.

- For transferring dry, packaged items in food factories.

- Locations without UV sterilization or electronic control requirements.

Semi-Automatic Pass Box - Mechanism and Advantages

Mechanism:

- Combines electronic interlock with semi-automatic controls.

- Some models have UV lamps that automatically turn on when the door is closed to sterilize surfaces.

- Doors can be opened smoothly with assistance from mechanical aids or electromagnets.

Advantages:

- Reduces manual effort during operation.

- Improves safety compared to manual Pass Boxes.

- Enhances sterilization efficiency in high-risk contamination areas.

Applications:

- Processing-packaging areas requiring surface sterilization.

- Food factories with moderate transfer frequency.

Automatic Pass Box - Features and Recommended Use Cases

Features:

- Fully automated operation with electronic control panel.

- Equipped with UV lamps, HEPA filters, door sensors, and alarms for incorrect operation.

- Can log activities or connect to cleanroom monitoring systems.

Recommended use cases:

- High hygiene requirement zones (e.g., instant food packaging, dairy processing, fresh product handling).

- Continuous production lines needing high-speed, hygienic transfers.

- Factories certified to HACCP, ISO 14644, ISO 22000.

Quick Comparison of Pass Box Types

|

Criteria |

Manual Pass Box |

Semi-Automatic Pass Box |

Automatic Pass Box |

|

Operation |

Manual |

Semi-automatic |

Fully automatic |

|

Interlock |

Mechanical |

Electronic + mechanical |

Electronic |

|

UV Lamp |

No |

Yes (auto-on when closed) |

Yes, programmable |

|

HEPA Filter |

No |

Optional |

Standard |

|

Safety |

Basic |

Medium |

High |

|

Maintenance |

Easy |

Medium |

Requires expertise |

|

Cost |

Low |

Medium |

High |

|

Main Uses |

Low-frequency, dry goods |

Medium sterilization need |

High hygiene, continuous lines |

3. Latest Price List for Pass Boxes in Food Factories

Reference Price Table by Model & Size

Prices are for reference only, based on common stainless steel 304 cleanroom-standard models.

|

Model |

External Dimensions (mm) |

Internal Dimensions (mm) |

Door & Interlock Type |

Extra Features |

Price (VND) |

|

PB-C500 |

600 x 600 x 600 |

500 x 500 x 500 |

Mechanical |

None |

8,500,000 - 9,500,000 |

|

PB-C600 |

700 x 700 x 700 |

600 x 600 x 600 |

Mechanical |

None |

9,800,000 - 10,800,000 |

|

PB-SD500 |

600 x 600 x 600 |

500 x 500 x 500 |

Electronic + mechanical |

UV lamp |

12,500,000 - 14,000,000 |

|

PB-SD600 |

700 x 700 x 700 |

600 x 600 x 600 |

Electronic + mechanical |

UV lamp |

14,500,000 - 16,000,000 |

|

PB-A600 |

700 x 700 x 700 |

600 x 600 x 600 |

Electronic |

UV lamp + HEPA filter |

18,000,000 - 21,000,000 |

|

PB-A800 |

900 x 900 x 900 |

800 x 800 x 800 |

Electronic |

UV lamp + HEPA filter |

22,000,000 - 25,000,000 |

Notes and Price Conditions

- Prices exclude 10% VAT and shipping/installation fees.

- Prices may vary based on:

- Material: SS304 or SS316.

- Additional features: sensors, control panels, logging systems.

- Custom sizes according to cleanroom design.

- Order quantity: bulk orders may receive discounts.

- Lead time: 7-15 days for standard units; 15-25 days for custom units.

- Standard warranty: 12 months with lifetime technical support.

How to Get an Accurate Quote Based on Technical Drawings

To receive the most accurate quotation, customers should prepare:

- Technical drawings or required dimensions of the Pass Box.

- Installation location and cleanliness level of each area (ISO 14644).

- Purpose of use (transfer of raw materials, finished products, tools…).

- Required features (UV lamp, HEPA filter, sensors…).

- Estimated quantity.

See more: 9 Key Considerations for Dynamic Pass Box Implementation

4. Criteria for Selecting the Right Pass Box for Food Factories

Corrosion-Resistant and Easy-to-Clean Material

- SS304: Popular for rust resistance, good corrosion resistance, and easy cleaning.

- SS316: Suitable for high-humidity environments or exposure to strong cleaning chemicals.

- Surface finish: Brushed or mirror-polished to prevent dust buildup and bacterial growth.

Tip: Prefer materials certified for FDA or EU Food Contact compliance.

UV Lamp Integration in High-Risk Areas

- UV lamps sterilize item surfaces during transfer, reducing cross-contamination.

- Recommended for:

- Transfers from raw material zones to processing areas.

- Packaging of instant food, confectionery, dairy.

- UV lamps should have safety sensors to auto-switch off when doors open.

Compatibility with Cleanroom Design and Workflow

- Dimensions: Must match installation space and item size.

- Door opening direction: Should align with material flow, avoiding workflow obstruction.

- Interlock system: Must sync with room pressure and cleanliness protocols (ISO 14644).

- HVAC integration: For HEPA-equipped Pass Boxes, ensure airflow matches system specs.

Warranty and After-Sales Service

- Warranty: Minimum 12 months with genuine spare parts replacement.

- Technical support: Engineers available for installation, operation, and maintenance.

- After-sales services:

- Supply of accessories, UV lamps, HEPA filters.

- Periodic inspection and calibration for performance.

- Quality assurance: Supplier should have ISO 9001 certification.

See more:Precautions on replacing filter for Pass Box

5. Relevant Standards and Regulations

HACCP Requirements for Pass Boxes

- HACCP (Hazard Analysis and Critical Control Points) manages food safety by identifying hazards and controlling CCPs.

- Pass Boxes act as physical control points to:

- Prevent cross-contamination during transfers.

- Ensure item transfers meet hygiene requirements.

Technical requirements:

- Food-safe materials (SS304/SS316).

- Easy to clean, no gaps for dust or bacteria.

- Interlock to prevent both doors opening simultaneously.

- UV lamp or HEPA filter in high-risk areas.

ISO 14644 - Cleanroom Standard

- Defines air cleanliness classification.

- Pass Boxes:

- Maintain pressure stability between rooms.

- Prevent air from lower to higher cleanliness areas.

Requirements:

- Air leak prevention.

- Smooth, dust-resistant surfaces.

- HEPA filters ≥ 99.97% efficiency at 0.3 microns.

ISO 22000 - Food Safety

- Integrates HACCP with quality management.

- Pass Boxes help by:

- Ensuring safe material/product transfer.

- Supporting hygiene control in continuous production.

- Easy integration into SOPs.

Additional requirements:

- Logging and monitoring (for electronic Pass Boxes).

- Regular maintenance with recorded logs.

6. FAQ

Is a Pass Box mandatory in food factories?

No, but it is a best-practice solution to meet hygiene standards in HACCP, ISO 14644, ISO 22000.

Manual or electronic Pass Box?

- Manual: Lower cost, easy maintenance.

- Electronic: Fully automated, UV + HEPA options for high hygiene needs.

How often should Pass Boxes be maintained?

Every 6 months, or every 3-4 months in high-frequency use.

Can Pass Boxes be custom-sized?

Yes, VCR manufactures to custom dimensions, materials, and features.

See more: Comprehensive Guidelines for Optimal Operation of Dynamic Pass Boxes

7. Contact & Quotation

VCR Cleanroom Equipment JSC - Full cleanroom solutions for food, pharmaceutical, cosmetic, electronics industries.

Contact us today for consultation on the most suitable Pass Box for your food factory.

Get a detailed quote within 24h with technical drawings and optimal solutions.

Special offers for bulk orders or turnkey cleanroom projects.

Hotline: 090.123.9008

Email: [email protected]

Website: https://Pass Box.vn

Diep VCR