Food cleanroom Pass Box that meets ISO 22000 is a safe transfer solution helping prevent cross‑contamination and ensure hygiene in food production.

- 1. What is a food cleanroom Pass Box?

- 2. How is ISO 22000 related to Pass Boxes?

- 3. Common types of Pass Boxes in the food industry

- 4. Criteria for choosing an ISO 22000‑compliant Pass Box supplier

- 5. Introducing VCR – Supplier of Cleanroom Pass Boxes for the Food Industry

- 6. Frequently Asked Questions (FAQ)

1. What is a food cleanroom Pass Box?

A Pass Box (also known as a Hatch Transfer Box) is a device used to transfer items between two areas with different cleanliness levels in a cleanroom environment. In the food industry, Pass Boxes are often installed at material, supplies, or product handoff points between production zones to limit microbial or particulate cross‑contamination.

Functions in the food industry:

-

Prevent cross‑contamination between rooms with different cleanliness levels

-

Minimize personnel movement (thus reducing the risk of carrying microbes or foreign particles)

-

Maintain pressure and cleanliness levels between ISO 14644 or GMP standard rooms

-

Improve production efficiency by optimizing material transfer without disrupting hygienic conditions

Is Pass Box mandatory in food factories?

According to food safety standards such as ISO 22000 and HACCP, food factories must control cross‑contamination risks at each stage. Thus, using a Pass Box that meets stringent hygiene criteria is required in critical microbiological control areas, such as:

-

Raw material processing

-

Aseptic packaging

-

Cold storage and finished goods warehouses

-

Microbiology testing rooms

A fully compliant Pass Box uses 304/316 stainless steel, has a cleanable structure free of dead corners, and includes interlocked locking mechanisms to prevent both doors from opening simultaneously.

Read more: Periodic cleaning and maintenance process of Pass Box

2. How is ISO 22000 related to Pass Boxes?

What is ISO 22000?

ISO 22000 is an international standard for Food Safety Management Systems, covering the entire food chain — from farms, processing plants, to consumers. It helps enterprises identify and control food safety hazards through a rigorous control system, integrating HACCP principles with requirements on hygienic design and operational controls.

Role of cleanroom equipment — especially Pass Boxes

In modern food plants, environmental control is critical to reduce microbial or particulate hazard. Production zones such as packaging, mixing, and material preparation often adopt cleanroom models and deploy supporting devices like Pass Boxes, Air Showers, HEPA filters, etc. A Pass Box enables safe transfer between rooms without breaking the airflow or introducing contaminants and is a potential weak point if poorly designed.

Why must Pass Boxes comply with ISO 22000?

To satisfy ISO 22000, Pass Boxes must meet certain requirements:

-

Food‑safe materials: typically stainless steel 304 or 316, non‑corrosive, chemically compatible with cleaning agents

-

Easy to clean, no dead corners: rounded internal corners, smooth surfaces, tight doors, daily cleaning accessibility

-

Cross‑contamination prevention: interlocking doors to avoid simultaneous opening, reducing airflow exchange

-

Optional HEPA filters: in high microbiological demand zones, integrate a HEPA fan/filter to reduce airborne particles

Also, in ISO 22000 audits, assessors examine usage logs, cleaning records, and maintenance history of equipment like Pass Boxes. Non‑compliant or undocumented devices may jeopardize certification.

Read more: Latest price list of Passbox used in medical clean rooms

3. Common types of Pass Boxes in the food industry

Different types of Pass Boxes help satisfy varying levels of microbial control and functional needs. Below are three commonly used forms:

| Type | Description | Typical Applications in Food Plants |

|---|---|---|

| Mechanical Pass Box | Manual doors, no filters or electronics | Used in less critical zones such as packaging material storage or sanitary supply rooms |

| Pass Box with HEPA fan/filter | Integrated HEPA system to blow clean air and reduce particulates | Suitable for handoff points between raw processing → packaging, or from corridor to clean zones |

| Electronic Interlock Pass Box | Electrically interlocked doors (only one door opens at a time), ensuring leakage control | Ideal for sterile packaging, mixing units, or finished goods zones with strict microbial control |

Recommendations by area:

-

Raw material processing area: use mechanical or HEPA Pass Boxes depending on proximity to clean zones

-

Packaging/assembly zones: use Pass Boxes with electronic interlock + HEPA

-

Finished goods warehouse adjacent to packaging: HEPA Pass Box ensures preservation of cleanliness during transfer

Selecting the correct type for each zone is essential not just for process optimization but also as a compliance requirement in ISO 22000 certified facilities.

Read more: Mechanical Pass Box and Electronic Pass Box: Advantages and disadvantages of use

4. Criteria for choosing an ISO 22000‑compliant Pass Box supplier

Choosing the right pass box supplier helps ensure compliance and long‑term reliability. Key evaluation criteria include:

-

Quality management certifications

-

ISO 9001: overall quality system

-

ISO 22000 or HACCP: demonstrates deep understanding of food industry requirements

-

-

Food‑grade materials

-

Stainless steel 304 or 316 is mandatory

-

Must provide certificates of origin (CO) and quality (CQ)

-

-

Design suitable for cleanroom environments

-

Rounded internal corners, no dead zones

-

Easy to open and clean

-

Options for HEPA, UV disinfection, electronic interlock

-

-

Technical documentation & verification

-

Technical drawings (layout integration)

-

Test reports, internal inspection records (IQ/OQ/PQ)

-

CO, CQ, as‑built documentation

-

-

Experience in food plant projects

-

Prefer vendors with reference cases in the food sector

-

Understanding of GMP, HACCP, ISO 22000 in design and implementation

-

-

Warranty & after‑sales support

-

At least 12 months of warranty

-

On‑site installation, maintenance and technical backup

-

Spare parts and upgrade path

-

Read more: Customized Passbox for Specialized Food Manufacturing Processes

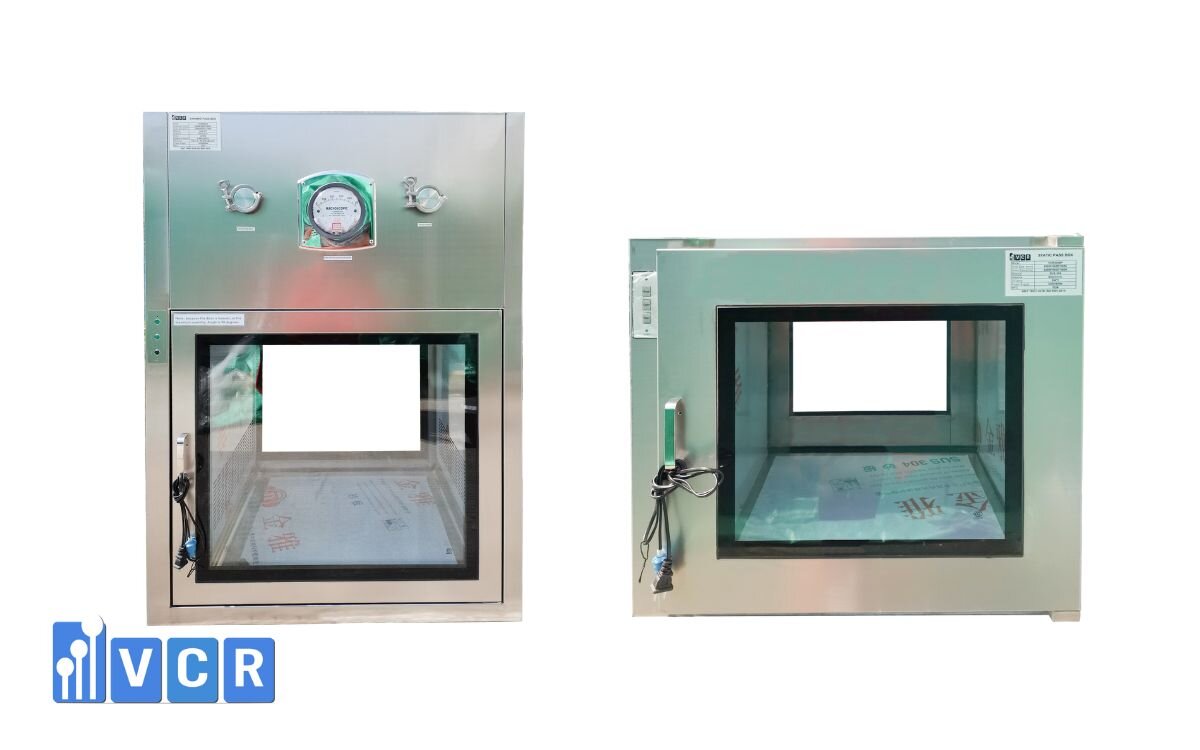

5. Introducing VCR – Supplier of Cleanroom Pass Boxes for the Food Industry

With increasing strictness on hygiene standards in food manufacturing, selecting a reputable cleanroom equipment provider like VCR can save cost, time, and help ensure ISO 22000 compliance from the outset.

-

VCR has over 10 years of specialization in cleanroom equipment

-

Their products meet high standards including GMP, ISO 14644, HACCP, and are well suited for ISO 22000

-

They have served many large food factories across the country, supplying and installing Pass Boxes, Air Showers, filtration systems, clean change rooms, etc.

-

VCR Pass Boxes: made of 304/316 stainless steel, no dead corners, easy to clean; optional features: electronic interlock, HEPA filters, UV lamps

-

They provide technical drawings, CO/CQ, operating instructions, and inspection documentation

Read more:GMP standard Pass Box supplier for pharmaceutical factories

6. Frequently Asked Questions (FAQ)

Is a food cleanroom Pass Box mandatory?

Yes. In controlled microbiological zones like packaging, mixing, or inspection rooms, a Pass Box is required by GMP and ISO 22000 to prevent cross‑contamination and maintain stable airflow.

Should I use a Pass Box with HEPA in food factories?

It depends on the zone’s microbiological requirement. For high‑risk areas (sterile packaging, mixing, microbiology labs), using a HEPA‑integrated Pass Box is recommended.

What certifications should a Pass Box have for ISO 22000?

It should come with:

-

CO (Certificate of Origin)

-

CQ (Certificate of Quality)

-

Use of 304/316 stainless steel

-

Clean design with no dead zones, chemically compatible surfaces

Does VCR support installation at the factory?

Yes. VCR has a technical team for site survey, consultation, installation, and long‑term technical support nationwide. They also provide technical drawings and documentation.

Contact

Hotline: 090.123.9008

Email: [email protected]

Website: https://passbox.vn/

Dat VCR