A dynamic pass box serves as a pivotal device for transferring items within a controlled clean environment, minimizing the frequency of door openings.

Primarily utilized for the transfer of small materials across cleanrooms of varying cleanliness levels or between cleanrooms and non-cleanrooms, a comprehensive understanding of its structural components and operational features is essential for optimal utilization.

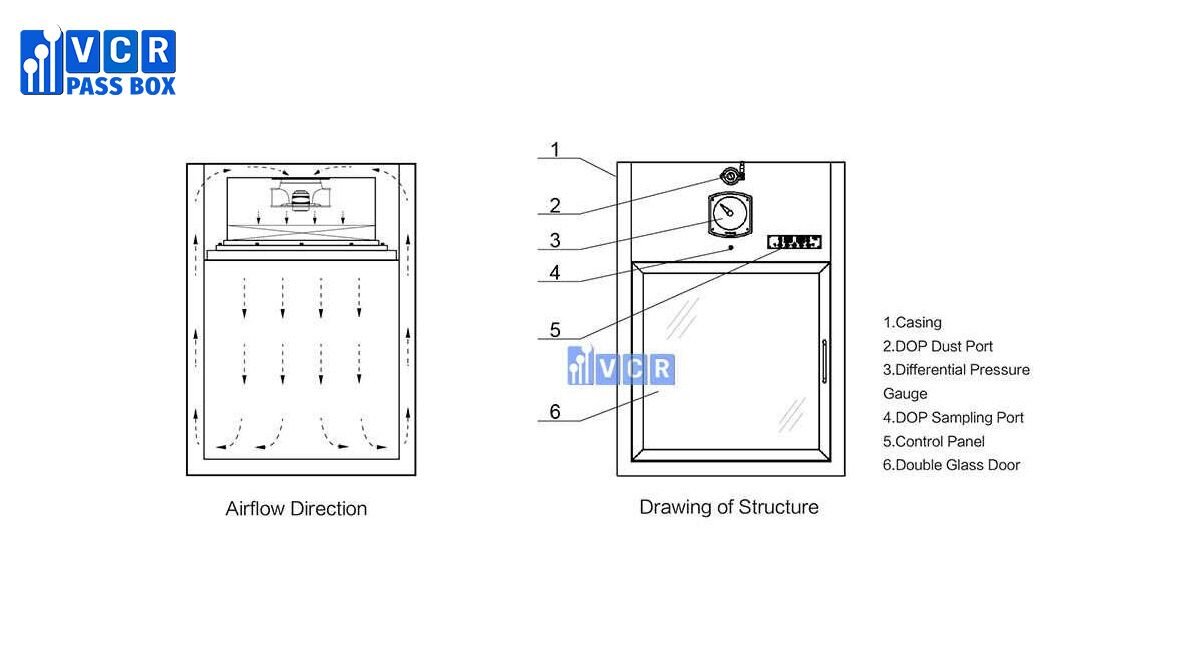

1. Dynamic Pass Box Structure

Comprising five integral components - Casing, DOP dust port, differential pressure gauge, DOP sampling port, control panel, and double-layer glass door - the dynamic pass box is meticulously designed to ensure effective and secure material transfer.

See more: Optimizing dynamic pass box

2. Outstanding Features

- Self-Cleaning Function: The pass box incorporates a self-cleaning mechanism, where a fan draws air through a HEPA filter to purify the internal environment during item transfer.

- Electronic Interlocking System: The doors employ an electronic interlocking system, ensuring that when one door is open, the other is automatically locked, preventing unauthorized access.

- Ultraviolet Disinfection Lamps: Equipped with UV lamps for disinfecting items that may not be effectively disinfected by conventional means.

See more: Optimal operation dynamic pass box

3. Working Principle

The dynamic pass box functions through a process involving a HEPA filter, a fan, and a return air grille. The air circulation is meticulously managed to maintain a purified environment around the conveyed items.

See more: Working principle of dynamic pass box

4. Design Requirements

- Cleanliness Requirements: Complies with Class B cleanliness standards.

- Seamless Design: The casing and chamber are seamlessly designed for optimal cleanliness.

- Laminar Airflow: Utilizes a laminar airflow design with vertical air movement.

- Filter Specifications: Utilizes G4 pre-filter and HEPA filter H13 or H14.

- Control System: Equipped with an on/off button, electronic interlock door button, and UV light switch.

See more: Design of Pass Box

5. Material Requirements

- Surface Material: Stainless steel plate (304) with a minimum thickness of 1.5mm for both inner and outer surfaces.

- Frame Material: 304 stainless steel frame with a minimum thickness of 1.2mm.

- Glass Material: Tempered glass with a thickness greater than or equal to 8mm.

- Hepa Filter Frame: Aluminum alloy for strength and shape.

See more: How to selecting Pass Box

6. Dynamic Pass Box Qualification

- Installation Qualification (IQ): Ensures compliance with equipment purchase contract requirements.

- Operational Qualification (OQ): Validates proper operation according to established standards.

- Performance Qualification (PQ): Documents the dynamic pass box's long-term adherence to quality standards under normal manufacturing conditions.

See more: Pass box for pharmaceuticals

7. Maintenance Protocols

- Regular replacement of filters with specified intervals and shutdown during replacement.

- Periodic cleanliness measurements and thorough sterilization.

- Proper procedures for HEPA filter replacement and maintenance checks.

See more: Validating pass box cleanroom

8. Precautions on HEPA Filter Replacement

- Attention to proper unpacking, handling, and installation to prevent damage to the filter.

- Visual inspection for leaks before installation.

- Strict adherence to replacement steps and airflow direction.

9. Usage Precautions

- Indoor usage and storage only.

- Adequate structural support in cleanroom floors and walls.

- Caution against direct UV light exposure to the eyes.

- Prohibition of opening both sides of the door without turning off the UV lamp.

- Strict adherence to usage guidelines to avoid structural modifications.

- Disconnection of power before UV lamp replacement.

See more: Air shower pass box

Conclusion

Understanding the intricate details of dynamic pass box design, operation, and maintenance is crucial for ensuring a controlled and clean transfer environment. Implementing the outlined guidelines and precautions will contribute to the efficient and safe utilization of dynamic pass boxes in various controlled environments.