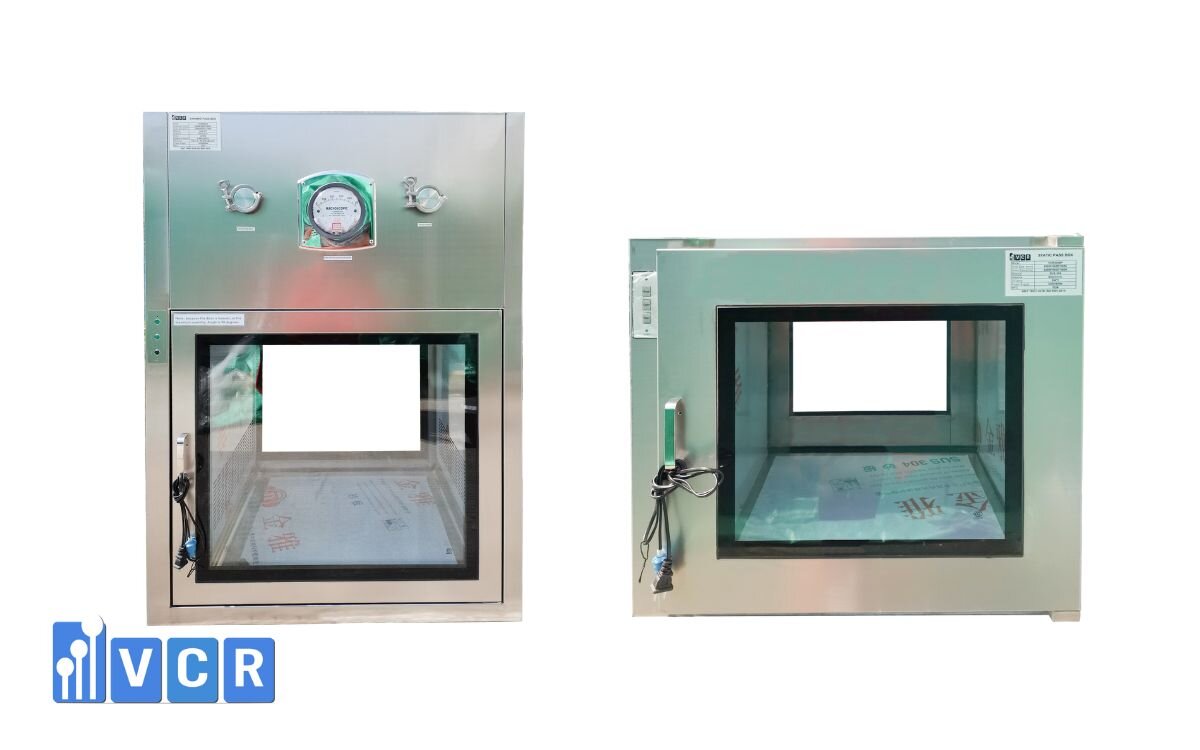

Pass Box is an important device in the clean room system, taking on the role of transferring items between areas of different cleanliness levels. To ensure sterile safety and avoid cross-contamination, it is mandatory to perform the "Periodic Pass Box Cleaning and Maintenance Procedure" to help maintain stable operating performance.

- 1. How Often Should a Pass Box Be Cleaned?

- 2. Why Is Regular Pass Box Maintenance Important in Cleanroom Environments?

- 3. GMP/ISO-Compliant Pass Box Maintenance Schedule

- 4. Common Issues When Pass Boxes Are Not Properly Maintained

- 5. Who Should Perform Pass Box Cleaning & Maintenance?

- 6. Quick Answers About Pass Box Maintenance

- 7. Need Scheduled Pass Box Maintenance? VCR Has You Covered

1. How Often Should a Pass Box Be Cleaned?

A Pass Box is an intermediary device used to transfer items between two cleanroom areas with different cleanliness levels. Without regular cleaning, it can accumulate dust and microorganisms, potentially becoming a source of cross-contamination throughout the production process.

Recommended Cleaning Frequency

Depending on the type of Pass Box and how frequently it is used, cleaning should follow this schedule:

|

Type of Pass Box |

Recommended Frequency |

|

Manual Pass Box |

After each shift or at the end of the day |

|

Pass Box with UV light |

Daily cleaning + weekly UV check |

|

Automatic/Electronic Pass Box |

Daily cleaning + monthly technical maintenance |

For cleanrooms in pharmaceutical, cosmetic, or food industries that follow GMP standards, cleaning should be planned and documented according to internal SOPs.

Key Areas to Clean

Focus on surfaces that are frequently touched or prone to contamination:

- Internal chamber: where materials are placed - must be sterile.

- Both access doors: clean door seals and hinges thoroughly.

- Handles, control buttons, and touch screens: wipe dry after disinfection.

- HEPA/Pre-filters (if equipped): clean with compressed clean air or replace as needed.

Recommended Cleaning Tools & Chemicals

|

Tools & Chemicals |

Purpose |

|

Lint-free, non-woven cloth |

Leaves no residue |

|

70% Isopropyl Alcohol |

Surface disinfection |

|

Neutral pH cleaning solution |

Removes organic residue |

|

Nitrile gloves |

Ensures hygiene and safety |

|

Handheld particle counter |

Measures cleanliness level post-cleaning |

Avoid using strong acids, high-alkaline cleaners, or any agents that may corrode stainless steel, glass, or damage painted surfaces.

5-Step Quick Cleaning Procedure

- Preparation: Wear proper PPE, sanitize hands, prepare clean cloth and cleaning agents.

- Dry wipe: Remove visible dust with a dry lint-free cloth.

- Wet wipe: Use a cloth moistened with alcohol or neutral cleaner to wipe all surfaces.

- Final dry wipe: Ensure no moisture or residue remains inside the chamber.

- Cleanliness check: Use a particle counter if applicable to verify results.

See more: GMP standard Pass Box supplier for pharmaceutical factories

2. Why Is Regular Pass Box Maintenance Important in Cleanroom Environments?

Maintaining a Pass Box regularly helps extend its service life, prevents cross-contamination, and ensures compliance with standards like ISO 14644, GMP, and HACCP.

Key reasons for routine maintenance include:

1. Preventing Physical & Microbial Cross-Contamination

Unclean chambers or doors may harbor dust and bacteria, which can be transferred during material handovers. In pharmaceutical environments, such contamination could lead to regulatory violations.

2. Protecting HEPA Filter and Motor Efficiency

Filters function best when airflow is unobstructed. Dust buildup increases pressure loss, strains the motor, and reduces the device’s operational lifespan.

3. Maintaining Cleanroom Differential Pressure

Leaks or buildup in the Pass Box may disrupt pressure differentials between rooms, compromising airflow integrity and potentially causing reverse airflow or microbial buildup.

4. Ensuring Regulatory Compliance

Pass Boxes are regularly inspected during GMP, ISO, or HACCP audits. Missing maintenance logs or improper upkeep can result in failed inspections and costly operational disruptions.

Regular maintenance is not optional—it is a regulatory and operational necessity in modern cleanroom environments.

See more: Latest price list of Passbox used in medical clean rooms

3. GMP/ISO-Compliant Pass Box Maintenance Schedule

To ensure reliable operation and regulatory compliance, Pass Boxes should be maintained according to the following timeline:

|

Frequency |

Maintenance Task |

Tools Required |

Notes |

|

Daily |

- Clean surfaces - Check door locking mechanisms |

- Lint-free cloth - 70% IPA |

After each production shift |

|

Weekly |

- Check interlock functionality - Inspect UV light |

- Screwdriver - Amperemeter |

For UV-equipped models only |

|

Monthly |

- Check airflow rate (if applicable) - Measure door delay time |

- Airflow meter - Stopwatch |

Record results in maintenance log |

|

Quarterly |

- Measure chamber pressure differential - Replace pre-filter |

- Pressure meter - Spare pre-filters |

Mandatory under GMP guidelines |

Maintenance Notes

- All maintenance should be recorded in a logbook or digital system for audit tracking.

- Never perform maintenance while the unit is operating or containing materials.

- If recurring issues are detected, escalate to a full inspection of interlocks, controllers, and filters.

Tip: Consider signing a maintenance contract with your equipment provider (such as VCR) to ensure proper and timely service by trained professionals.

4. Common Issues When Pass Boxes Are Not Properly Maintained

If a Pass Box is not regularly cleaned and maintained, technical failures and contamination risks can compromise cleanroom integrity, severely affecting product quality and audit results.

Common issues observed in practice include:

Faulty interlock mechanism (door locking failure)

- Symptoms: Both doors open simultaneously or delay in locking.

- Consequences: Clean air is lost, disrupting differential pressure between rooms → unbalanced airflow → increased risk of cross-contamination.

UV light malfunction (for models with UV)

- Symptoms: UV lamp does not light up or flickers abnormally.

- Consequences: Microorganisms are not disinfected prior to material transfer, increasing the risk of microbial contamination in the production process.

Reduced HEPA filter performance

- Symptoms: Lower airflow, increased inlet pressure, weak air delivery.

- Consequences: The Pass Box may not meet required ISO Class 5-7 standards, leading to non-compliance in ISO 14644 or GMP audits.

Accumulated dust and stained chamber

- Symptoms: Persistent stains, discolored or dusty rubber seals.

- Consequences: Dust buildup can become microbial hotspots, directly impacting product quality, especially in pharmaceuticals and cosmetics.

See more: Pass Box Maintenance in Hospital Cleanrooms: Ensuring Sterility and Longevity

5. Who Should Perform Pass Box Cleaning & Maintenance?

Pass Box maintenance should only be carried out by properly trained personnel, as this equipment is critical in maintaining cleanroom integrity during material transfer.

In-house - Factory Technical Department

- Who? Maintenance staff or technicians trained under internal SOPs.

- Advantages: Flexible scheduling, prompt minor issue handling, cost-effective.

- Requirements: Must follow GMP/ISO-approved cleaning and maintenance procedures.

Note: It is recommended to use a detailed checklist and maintain a maintenance logbook for audit traceability.

External - Equipment Supplier or Service Provider

- Who? Qualified technicians from equipment suppliers, such as VCR.

- Advantages: Specialized expertise, full access to diagnostic tools (pressure, airflow, UV, HEPA).

- Best for: Facilities requiring certified inspections for GMP/ISO compliance.

VCR currently offers scheduled Pass Box maintenance services, complete with detailed GMP/ISO-compliant reports to help manufacturers pass audits confidently.

Required: Maintenance & Calibration Records

Each maintenance session must be fully documented, including:

- Date and time

- Person in charge

- Inspection items

- Equipment used

- Measurement results

These records must be stored for at least 12 months for internal QA reviews or external inspections (GMP, ISO, HACCP, etc.).

See more: Optimizing Pass Box Requirements in Negative Pressure Environments

6. Quick Answers About Pass Box Maintenance

1. Do I need to clean the Pass Box daily?

Yes. Daily cleaning is mandatory for units located in critical zones like weighing rooms, packaging areas, or where materials are exposed.

2. When should the HEPA filter be replaced?

Typically every 6-12 months depending on usage and environment. If pressure readings exceed the limit, the filter should be replaced immediately to maintain cleanliness levels.

3. Can we perform Pass Box maintenance in-house?

Yes, if staff have been properly trained and follow internal SOPs. However, for units with air blowers or electronic interlocks, it’s advisable to hire certified technicians to avoid technical issues.

4. What are signs the Pass Box needs urgent inspection?

- Flashing error lights

- Doors not locking properly

- Unusual delay in door operation

- Strange odors or fine dust in the chamber, indicating filter issues or contamination

7. Need Scheduled Pass Box Maintenance? VCR Has You Covered

Keeping your Pass Box in optimal condition and compliant with GMP/ISO is essential for maintaining product quality and passing audits without complications.

VCR - Your Trusted Technical Partner

With over 10 years of experience in cleanroom equipment supply and maintenance, VCR provides:

- Routine inspection, cleaning, and part replacement

- Technical reports compliant with GMP/ISO standards

- Nationwide service, tailored to your production shifts

Contact us today for a consultation or service package tailored to your cleanroom needs.

Hotline: 090.123.9008

Email: [email protected]

Website: https://passbox.vn/

Diep VCR