In the world of biotechnology and pharmaceuticals, maintaining sterility is paramount. Enter the VHP pass box, a vital tool for transferring materials between classified areas while ensuring complete decontamination. But like any technology, it comes with its own set of advantages and disadvantages.

Let's delve deeper into this essential equipment, exploring its strengths and limitations to guide informed decision-making for your cleanroom needs.

Why use VHP?

Traditional sterilization methods like high temperatures and ethylene oxide gas pose limitations for certain materials. VHP (Vaporized Hydrogen Peroxide) emerges as a game-changer. Its low-temperature application (4-80°C) makes it ideal for heat-sensitive products, while its efficacy against a broad spectrum of microorganisms, including Bacillus stearothermophilus, is undeniable. Furthermore, VHP decomposes to harmless water and oxygen, promoting environmental sustainability.

See more: What is VHP Pass Box

Advantages of VHP Pass Boxes

- Effective and Versatile Sterilization: VHP penetrates even hard-to-reach areas, providing excellent kill rates for various contaminants. Its suitability for diverse materials expands its utility across various applications.

- Low-Temperature Processing: Heat-sensitive products, previously considered challenging to sterilize, can now be safely treated with VHP, safeguarding their integrity and functionality.

- Enhanced Containment: Interlocking systems and robust sealing eliminate the risk of cross-contamination during material transfer, protecting your cleanroom environment.

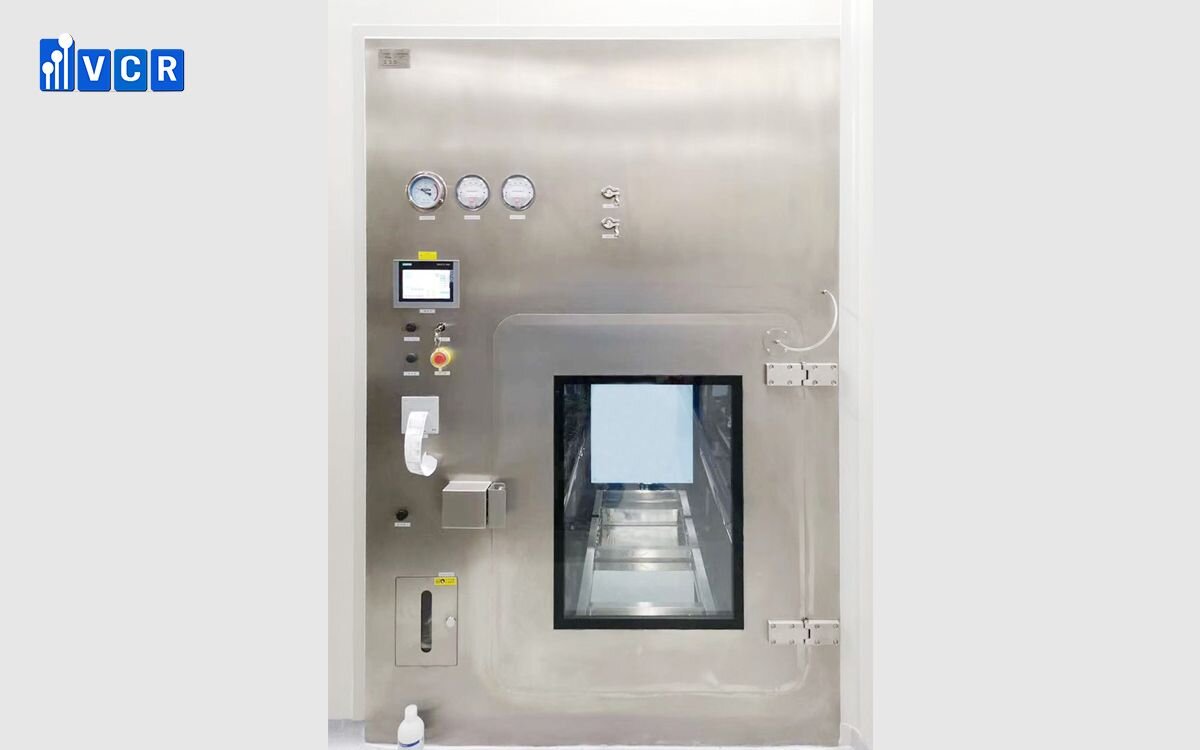

- User-Friendly Operation: Advanced control systems with intuitive touchscreens simplify operation, ensuring process consistency and ease of use.

- Environmentally Friendly: VHP decomposes to water and oxygen, minimizing chemical waste and contributing to a sustainable cleanroom operation.

- Cost-Effective: Efficient sterilization with low hydrogen peroxide consumption and short cycle times translates to operational cost savings.

See more: What is Pass Box

Disadvantages to Consider

- Extended Sterilization Cycle: Compared to some methods, VHP sterilization can take longer, ranging from 1.5 to 3 hours depending on chamber size. Early material removal with residual H2O2 poses safety risks.

- Temperature Sensitivity: Although low-temperature compared to traditional methods, the VHP process can still raise internal temperatures (5-15°C), potentially impacting biological or temperature-sensitive materials.

- Hydrogen Peroxide Hazards: Concentrated hydrogen peroxide (30-35%) is flammable and requires careful handling. Additionally, impurities in the solution can affect equipment lifespan.

Conclusion:

VHP pass boxes offer a powerful and versatile solution for cleanroom sterilization, particularly for heat-sensitive materials. However, a comprehensive understanding of their advantages and disadvantages is crucial for informed decision-making. Weighing factors like specific needs, processing times, and material compatibility will guide you towards the optimal sterilization technology for your controlled environment.